Vine Ripe – Tuscaloosa County Couple Wows Customers With Hydroponic Tomatoes

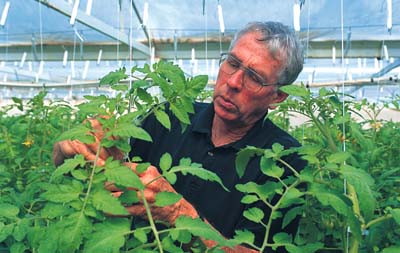

Visitors to John and Emily Bruce’s farm in Coker, Ala., can hardly believe their eyes. Even in the dead of winter, vine-ripened tomatoes paint the tabletops of their greenhouse with hues of red while a nearby sign directs customers to weigh their purchases and drop their money in a black mailbox.It is perhaps the best example of high-technology meets old-fashioned honesty, and the Bruces wouldn’t have it any other way. “As far as I know, I haven’t missed a tomato,” John said. “I think the people who will drive out here and find us, want tomatoes, and they are willing to pay for them.”But how can they sell ripe tomatoes in the winter? Well, they’re not importing them from Mexico. John said the secret is hydroponics.It all started a few years ago when Emily, then president of the West Alabama Day Lily Club, participated in a tour of Mississippi greenhouses. She came home telling John about a man who was selling ripe tomatoes in May. John called the man and soon was reading everything he could find about hydroponics.Today, “Miss Emily’s Vine Ripened Hydroponic Tomatoes” is a thriving business. Customers drive from miles around to get their wintertime tomato fix and to stare in awe at the ingenious system that allows the Bruces to harvest fruit during some of the coldest months of the year.John explained that the process starts with seeds that are planted in small cubes of rock wool. Trays containing 160 cubes each are bottom heated under florescent lights in the Bruces’ basement. A week to 10 days after the plants emerge, John moves the trays to the greenhouse, where he transplants the cubes into 3-inch pots filled with ground coconut hulls (also called coir).The self-taught tomato farmer said the coarse mixture is the perfect medium for hydroponic plants because it has little nutrient value but will hold up to 30 times its weight in water. The same mixture is used to fill 5-gallon plastic bags, which John moves the plants to after they are several inches tall.Two plants are placed in each bag, and the bags are lined up in long rows inside the greenhouse. Each is equipped with a spike that feeds the plants with a mixture of water, fertilizer and calcium. The feeders are triggered by a solar cell in the ceiling of the greenhouse.After a few months, John’s 1,000 or so plants transform the greenhouse into a jungle. The long rows resemble vine-covered walls as the tomatoes strain upward toward the sky. But keeping the plants growing requires a lot of hands-on attention–John’s hands.Working 40-50 hours a week, John carefully breaks off any side shoots, so the vines will produce one main stem. As the vines grow, he uses plastic clips to attach the stems to twine he’s suspended from the ceiling. The plants, which require 20 percent less sunlight that garden varieties, grow in a predictable pattern. They put on three leaves, then a cluster of tomatoes, then another three leaves, and so on. John thins the young tomatoes, leaving only three per cluster. As the tomatoes near the bottom of the plant ripen, he prunes the dying leaves and lowers the bare trunk onto the greenhouse floor.By the end of the season, this process creates towering plants that can yield up to 15 pounds each.But there’s more to growing hydroponic crops than just thinning and pruning–a lot more. Because there’s no wind and few insects in the greenhouse, each plant must be pollinated by hand. John uses a hand-held massager that he’s equipped with a long spike to shake the pollen loose from the blooms. In addition, he routinely checks the calibration of the irrigation system and checks the solution for acidity and nutrient value.”We test everyday because, if the you’re feeding them wrong, it’s all wrong,” John said.Disease and insects also are a concern in hydroponic greenhouses. So, John uses a natural bacterium to control white flies and aphids and a special fungicide called OxiDate to control blight, powdery mildew and mold. Catching disease early, John said, can mean the difference between a good crop and no crop at all. “You’ve got an environment here that, if you get something, it will go through the house like fire,” he said.The Bruces plant two crops of hydroponic tomatoes each year. The first seeds go in the ground on July 23 (John’s birthday), and tomatoes begin ripening by Halloween. The second crop is planted on Thanksgiving and bears fruit from late March to mid June.”We hope to have tomatoes into the third week of June,” John said. Once people get tomatoes in the field, we don’t want them because we can’t compete price wise. To come out, we need about $2 a pound.”John sells about 500 pounds of tomatoes a week at his greenhouse. His tomatoes also are available at V. Richards’ Market in Birmingham, and are used on salads at Tuscaloosa’s Cypress Inn Restaurant.”The taste is fantastic because we let them turn red on the vine,” John said. “When the color goes in, the flavor goes in. The more color they have, the better they are. If you pull them green, they are no better than Mexican tomatoes.”John said his greenhouses are always open to customers or folks who are just curious about how hydroponic tomatoes are grown. From Tuscaloosa, visitors can take Hwy. 82 west until the road narrows to two lanes; then turn left at mile marker 39 and follow the arrows on utility poles to Miss Emily’s greenhouse–and don’t forget to ask for some of Miss Emily’s favorite tomato recipes.For more information, contact John at (205) 339-3318.